UVA light-curing

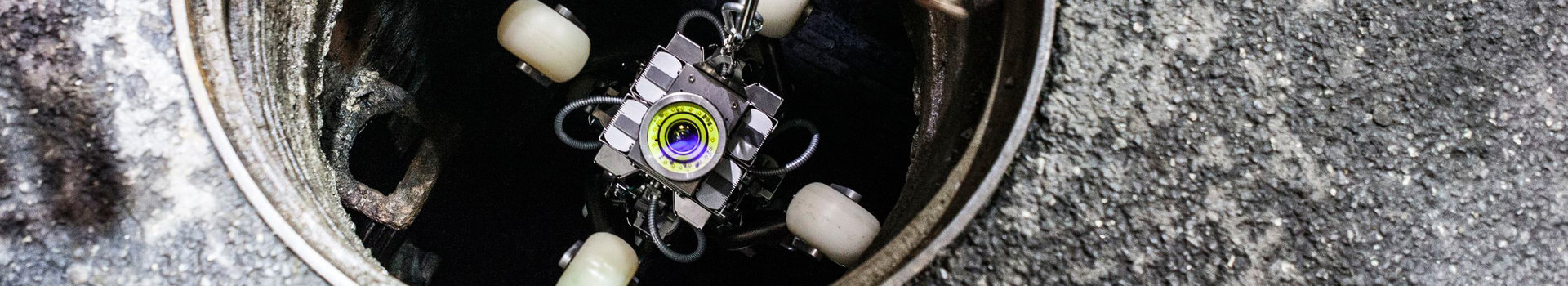

Innovative UVA light-curing technology

The quality of an installed GRP inliner depends strongly on the applied curing technology. Knowing this, Brandenburger founded its UV Reline.tec subsidiary in 1997, a company specialising in UVA design.

Uniform Curing

In the 1990s, Brandenburger's UVA light technology made an optimised and controlled light curing process possible for the first time. The entire process is controlled electronically and optically using TV cameras.

Keyword: Combination Curing

Even with GFRP pipe liners, stress analyses for larger oval profiles or mechanically demanding conditions often require wall thicknesses greater than 10 mm. For these rehabilitation cases Brandenburger has developed the so-called "combination curing".

For this the light-curing resins are mixed with a small amount of heat-curing peroxides. The curing process is done by the combination of light and heat curing, but without separate heat application in the form of steam or hot water. The exothermic reaction induces the intended heat curing in addition to the light curing and reliably cures the laminated liner even at greater wall thickness. Using the Brandenburger combination curing, rehabilitations can be carried out regardless of the necessary wall thickness. The curing speeds are similarly fast even for this procedure.

Background Information on Light Technology

UVA light curing has generally been applied industrially for over 30 years, for instance for curing paints in the automobile industry. This curing technology has also been used for sewer rehabilitation since the end of the 1980s.

In the light-curing procedure, the resin to be cured (UP or VE resin) is exposed to light of a specific wavelength (360–420 nm). Special light initiators in the resins ensure that the intended reaction occurs. In the resins being used, UV light can only induce polymerisation when free radicals are present. Exposure to UVA-light causes the “photoinitiator molecules” to decompose into the radicals that are required for the polymerisation process.

These induce polymerisation by interlinking with the styrols contained in the resin making a high-strength composite material.